The surgical instruments manufacturing cluster is mainly located in and around Sialkot, Punjab, Pakistan covering about 99% of the country’s production with GDP contribution of 0.13%. The cluster comprises of over 3600 companies including industrial units, vendors & traders and employs around 100,000-150,000 workers. This industrial cluster produces a wide range of surgical and beauty instruments for international producers / brands with diversified range of designs on their demand. Almost 95% production is export oriented. Almost all the firms are exporting, however, there are many vendor units that usually supply to commercial exporters/traders.

The surgical instruments manufactured in Sialkot are highly acknowledged all over the world due to their quality. The advanced countries of Europe and America are the leading buyers of Pakistan’s surgical instruments. The industry belongs to the light engineering industry category, and is one that has specialized in skill and stable export market share. Stainless Steel (both imported as well as local), Titanium, Brass and Aluminium are major industrial inputs. Surgical Instrument Manufacturing Association of Pakistan (SIMAP) is actively engaged to promote and safeguard the interests of this cluster.

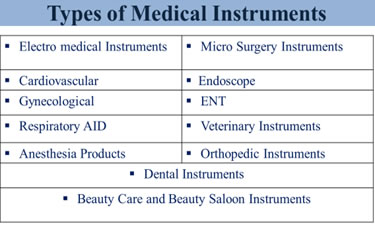

The following types of medical instruments are manufactured in Sialkot:

Pakistan is exporting surgical instruments to the world market mainly under Harmonized System (HS) Code 90. More than 95% of country’s export is under HS Code 9018 which covers Instruments and appliances used in medical, surgical, dental or veterinary sciences, including scintigraphic apparatus, other electro-medical apparatus, sight-testing instruments & Neuro Endovascular Surgery (NES). Pakistan has 0.30% share in the world trade i.e. $112.543 billion.

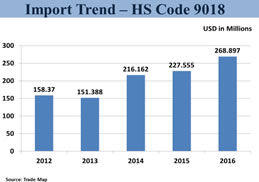

The historical review of Pakistan’s import and export under HS Code 9018 is as under:

|  |

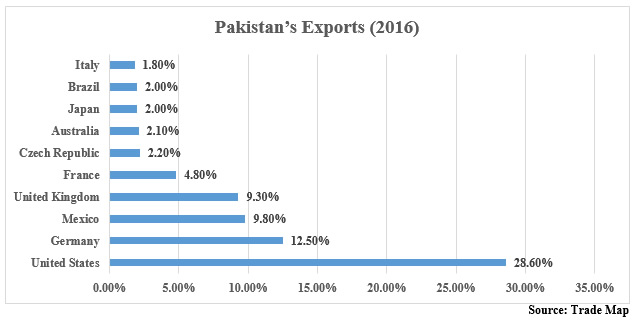

The top ten (10) export destinations are shown below:

At present, the surgical cluster of Sialkot is facing many challenges including shortage of skilled labor, absence of latest technology & product development techniques, non-availability of standardized raw material at affordable rate, strict compliance requirements, market and product diversification, poor marketing techniques, price war among cluster companies and cluster governance. Despite various issues and challenges being faced by the cluster, many advancements including branding and developing basic design capabilities etc. have been made by various cluster companies. It is need of the day to focus on this cluster and make various interventions to make it cluster self-sustainable by increasing productivity, export contribution, import substitution and technological up-gradation.